- Help Center

- Plate

- Aligning Plate

Using the Clamps and the Leveling Feet

The anti-slip mat on Plate ensures that it won't move while cutting, but there are cases where further clamping will be necessary.

Never use double-stick tape to hold Plate to a work surface. This can damage the anti-slip pad affixed to the underside.

To affix Plate to a work surface, use the clamping points (the keyhole inserts on the body of Plate) and/or the Accessory Rails.

Using the Clamps

Plate comes with specialized clamps for affixing it onto a workpiece or table. These clamps are designed to ensure they sit flush on the clamping points while being safe to use against the material. Follow this process to clamp Plate:

-

Place Plate on the surface and make sure it's sitting flat

-

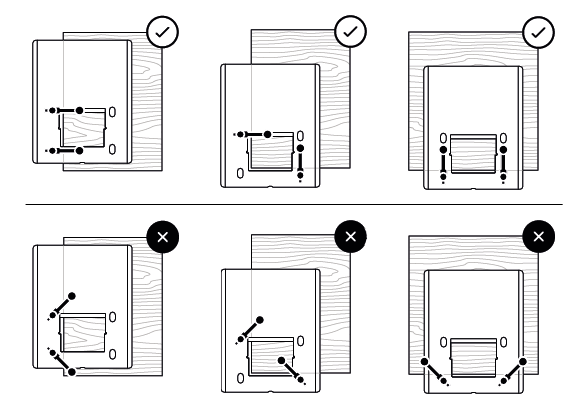

Insert the clamp into the clamp point and align it straight relative to Plate's edges per the above graphic

-

Tighten the clamp to touch-tight. Over clamping can cause Plate to bow.

Clamping Best Practices

It's best to clamp parallel to the orientation of Plate. Clamping at an angle relative to the sides can slip or otherwise not hold well. The clamping points are placed to optimize workholding with pressure that's parallel to the body of Plate.

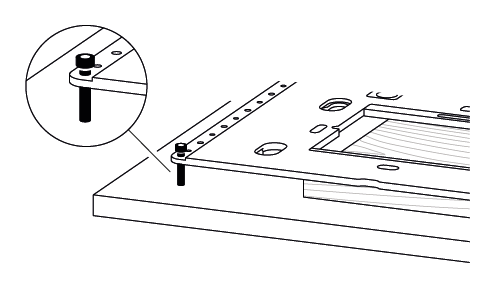

Using the Leveling Feet

The threaded holes on the outer edges of Plate can be used to install the Leveling Feet. These will help support Plate when it's overhanging an edge. They can be screwed into place as needed and adjusted in height by turning them until they sit flush.