Scanning Tips

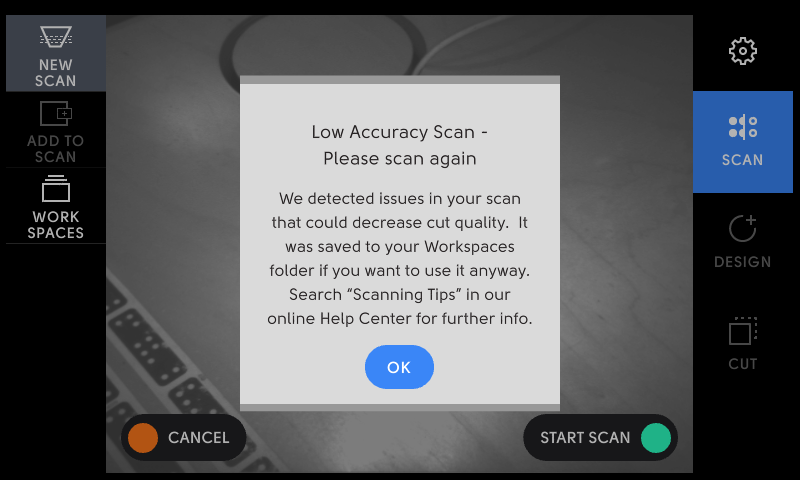

A "Low Accuracy Scan" error message indicates that Origin was unable to create a high quality image of your workspace.

The following are potential workspace problems that can lead to poor scans:

Insufficient Tape

Often, a low quality scan can be improved by adding more tape to the workspace, especially in the case in which tape has been cut.

Taping Problems

See here for a more in-depth discussion of common mistakes that users make when setting up their tape arrays. Here's a summary of things to look out for:

-

Tape that is not coplanar

-

Tape placed on a warped surface

-

Tape spanning two non-contiguous pieces of material

-

Discarded tape not attached to a workpiece but still within Origin's field of vision

-

Tape overlapping other tape

-

Bubbled or creased tape

Scanning Orientation

When scanning, try to keep Origin facing in the same cardinal direction throughout your scan. This will allow you to use less tape (since Origin's camera will always be facing in the same general direction) and will help you reduce the possibility of any inaccuracies when cutting.

Learn more about how best to keep Origin facing tape by watching the video below

Workspace Lighting

Certain low-quality LED lights can cause issues with Origin's vision system because they do not properly filter the flicker in the 50/60 Hz that powers the lights. Problems can also occur if your workspace has significant lighting during your cutting session.

Workspace Veiling

Some materials give off a glare or reflection under certain lighting conditions that will cause issues with Origin's vision system. Aluminum and some highly reflective black plastics have been problematic in the past. You can try to adjust your workspace or the lighting to eliminate glare. Alternately, you can consider roughing up the work surface or otherwise treating it to reduce its sheen.